Services

A17.3 Upgrades

Elevator A17.3 Upgrades: Essential Safety Modernization Solutions

Elevator safety standards continue to evolve to safeguard building occupants and ensure dependable vertical transportation. A17.3, developed by the American Society of Mechanical Engineers (ASME), outlines retroactive requirements for existing elevators and escalators nationwide. These standards form the foundation for state and local regulations that building owners must follow.

By implementing A17.3 upgrades, building owners can

enhance safety features, improve system reliability, and ensure full compliance with current codes while protecting their investment and occupants. The upgrades encompass critical components like safety doors, emergency communication systems and modern braking mechanisms.

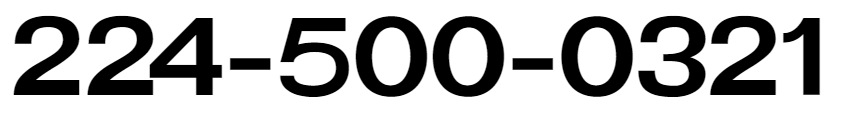

We at

Mountain Cross Consulting guide building owners through the complete A17.3 upgrade process, from initial assessment to final implementation. Our expertise helps modernize elevator systems with essential safety features while minimizing disruption to daily operations.

Essential Elements of Elevator A17.3 Upgrades

Elevator A17.3 upgrades require specific safety modifications and technical enhancements to meet modern standards. These critical improvements focus on passenger protection, equipment reliability and code compliance.

Understanding ASME A17.3 Standards

The ASME A17.3 Safety Code for Existing Elevators and Escalators establishes mandatory requirements for older installations. This code, first published in 1986, serves as the foundation for state and local regulations nationwide.

We recognize that A17.3 differs from A17.1 in its specific focus on existing equipment rather than new installations. The code addresses safety concerns through periodic updates, with the most recent edition released in 2023.

Building owners must implement these standards within 6 months of code adoption in their jurisdiction. The requirements apply to various vertical transportation systems, including electric elevators, hydraulic elevators and escalators.

Key Components of Elevator Upgrades

Critical Safety Elements

- Door operation and interlocking mechanisms

- Emergency communication systems

- Fire service operation controls

- Lighting and signage requirements

- Brake system modifications

Equipment Modernization

- Control system updates

- Machine room safety devices

- Hoistway equipment improvements

- Emergency power systems

- Seismic protection measures

These components operate as a unified safety system—designed to safeguard both passengers and maintenance personnel throughout every phase of elevator operation.

Retroactive Requirements and Code Updates

A17.3 requires all existing elevators to meet retroactive safety standards, regardless of their installation date. Local authorities decide when these rules are enforced.

We implement upgrades based on local code enforcement schedules and building-specific needs.

- Emergency stop switches

- Speed governors

- Position indicators

- Car and counterweight safeties

- Operating devices and control systems

Regular code updates ensure continued safety improvements as technology and safety standards evolve.

Compliance and Safety Benefits of A17.3 Upgrades

A17.3 upgrades provide essential safety improvements and ensure elevators meet current standards while protecting building owners from liability and non-compliance penalties. These upgrades directly impact the safety of passengers and increase property value through modern safety features.

Enhanced Elevator Safety and Performance

A17.3-compliant features reduce the chance of accidents by integrating improved door safety technology and reliable emergency braking. The upgrades include enhanced door closing force regulators and photoelectric reopening devices to prevent passenger injuries.

Upgraded controls ensure precise stops and smooth acceleration, reducing trip hazards. Emergency systems now support reliable two-way communication.

New lighting requirements improve visibility in elevator cars and hoistways, while upgraded maintenance access features protect service personnel.

Door restrictors to prevent accidental shaft access- Enhanced emergency lighting systems

- Modern safety edges and sensors

- Updated fire service operations

Meeting Legal and Regulatory Standards

ASME A17.3 compliance shields building owners from potential legal issues and ensures adherence to mandatory safety regulations. Regular code updates require existing elevators to meet new safety standards.

Each system includes protective circuits that watch over key components and instantly shut down the elevator when unsafe conditions appear.

Fire recall systems that meet current fire code requirements- Modernized emergency stop switches

- Updated seismic protection features

- Phase I and Phase II firefighter's emergency operations

Our upgrades satisfy both state and local inspection requirements, helping to avoid costly violations and potential shutdowns.

Increasing Property Value and Longevity

A17.3 compliance strengthens a property’s market position, reduces ongoing maintenance and delivers peace of mind. Modern safety and reliable operation appeal to tenants and elevate property values.

Updated components extend elevator lifespan by

- Reducing wear on mechanical systems

- Preventing premature equipment failure

- Minimizing unexpected breakdowns

- Improving energy efficiency

These improvements result in decreased insurance premiums and reduced liability exposure for building owners. Regular maintenance becomes more straightforward and cost-effective with modernized equipment that meets current standards.

Frequently Asked Questions

Building owners and facility managers require clear guidance on elevator safety standards, compliance requirements and upgrade processes. These answers address common concerns about A17.3 implementation and maintenance.

What is the purpose of ASME A17.3 standards in elevator safety and operation?

ASME A17.3 standards establish safety requirements for existing elevators, escalators and related equipment. These codes protect passengers and maintenance personnel through specific safety measures and operational guidelines.

The standards focus on critical safety features like door operations, emergency communications and brake systems. They provide measurable benchmarks for elevator performance and maintenance.

Why is it necessary for buildings to undergo Elevator A17.3 upgrades?

Buildings must meet current safety codes to maintain legal compliance and protect occupant safety. A17.3 upgrades address potential safety risks in older elevator systems that don't meet modern standards.

These upgrades prevent accidents and reduce liability for building owners. Regular modernization also extends equipment life and improves reliability.

What components are involved in an Elevator A17.3 upgrade process?

Key components include safety door interlocks, emergency communication systems and fire service features. Upgrades often involve modernizing control systems and installing new braking mechanisms.

The process includes lighting improvements, updated signage and enhanced emergency stop functions. Each component undergoes thorough testing after installation.

How does compliance with Elevator A17.3 standards affect a building's property value and safety?

A17.3 compliance increases property marketability through documented safety improvements. Modern elevator systems attract tenants and reduce insurance costs.

Safe, reliable elevators reduce liability risks and maintenance expenses. Updated systems operate more efficiently, leading to lower energy costs.

What types of services and support does Mountain Cross Consulting provide post-Elevator A17.3 upgrade?

We provide 24/7 emergency response and regular maintenance inspections. Our team conducts performance monitoring and preventive maintenance to ensure continued compliance.

We maintain detailed service records and provide technical support for building staff. Regular testing ensures all safety features function properly.

Can the implementation of Elevator A17.3 upgrades be tailored to individual buildings?

We customize upgrade plans based on building age, usage patterns and existing equipment condition. Each plan is customized to building conditions while meeting all required code standards.

Engineers carefully analyze existing systems, offering recommendations that meet safety requirements without exceeding budget limits.